MITUTOYO'S NEW STANDARD OF PRECISION

MITUTOYO CRYSTA-APEX V SERIES

CNC COORDINATE MEASURING MACHINE - 500 / 700 / 900 SERIES

Introducing Mitutoyo's new CNC coordinate measuring machine focused on accuracy, speed, and versatility. The CRYSTA-Apex V series offers multi-sensor flexibility with vision, laser, surface finish and scanning probe technologies. In addition, the AV series also supports a wide range of measurements and variety of workpieces, improving overall productivity and reducing downtime. The CRYSTA-Apex V Series is anew generation CNC coordinate measuring machine (CMM that helps make the smart factory—a factory that leverages IoT for the advanced management of production and quality information—a reality.

CHECK OUT OUR INFORMATIONAL VIDEO ON THE CRYSTA-APEX V BELOW:

CRYSTA-APEX V SERIES

A brand new design that conveys cutting-edge capabilities and creativity. An extensive product lineup that covers a wide range of measurements, from small to mid-sized workpieces. The new CRYSTA-Apex V series design distinguishes this generation of Smart Measuring Systems (SMS), from the previous model that includes cutting edge IoT* capabilities for this precision measuring instrument. With a lineup of three width sizes / ten models covering measurements of small to mid-sized workpieces, the CRYSTA-Apex V Series delivers further advances in accuracy, performance, speed, and versatility.

Precise + Effective + Absolute

CRYSTA-APEX V 544

Measuring ranges ( 2 sizes )

X: 500 mm

Y: 400, 700 mm

Z: 400 mm

CRYSTA-APEX V 776

Measuring ranges ( 2 sizes )

X: 700 mm

Y: 700, 1000 mm

Z: 600 mm

CRYSTA-APEX V 9106

Measuring ranges ( 6 sizes )

X: 900 mm

Y: 1000, 1600, 2000, mm

Z: 600, 800 mm

Note: All models incorporate a main unit Startup system (relocation detection system), which disables operation when an unexpected vibration is applied or the machine is relocated. Be sure to contact your nearest Mitutoyo Sales Office prior to relocating this machine after initial installation.

HIGH PRECISION

Absolute Quality

Provides accuracy that is unmatched by any previous general-purpose measuring machine through features that include the following:

A real-time temperature compensation system that greatly contributes to measurement accuracy; a maximum permissible length measurement error of 1.7 µm (i.e. 2 µm uncertainty for a measured length of 100 mm) guaranteeing high-accuracy measurements of the most intricate workpieces; and enhanced repeatability.

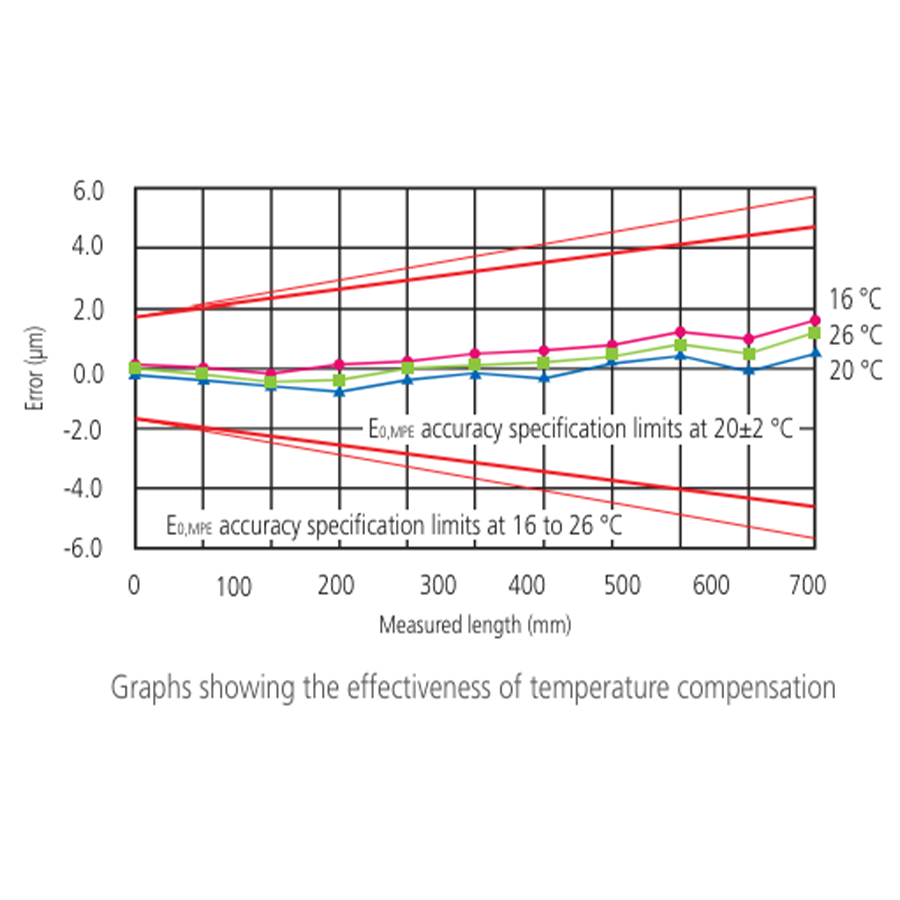

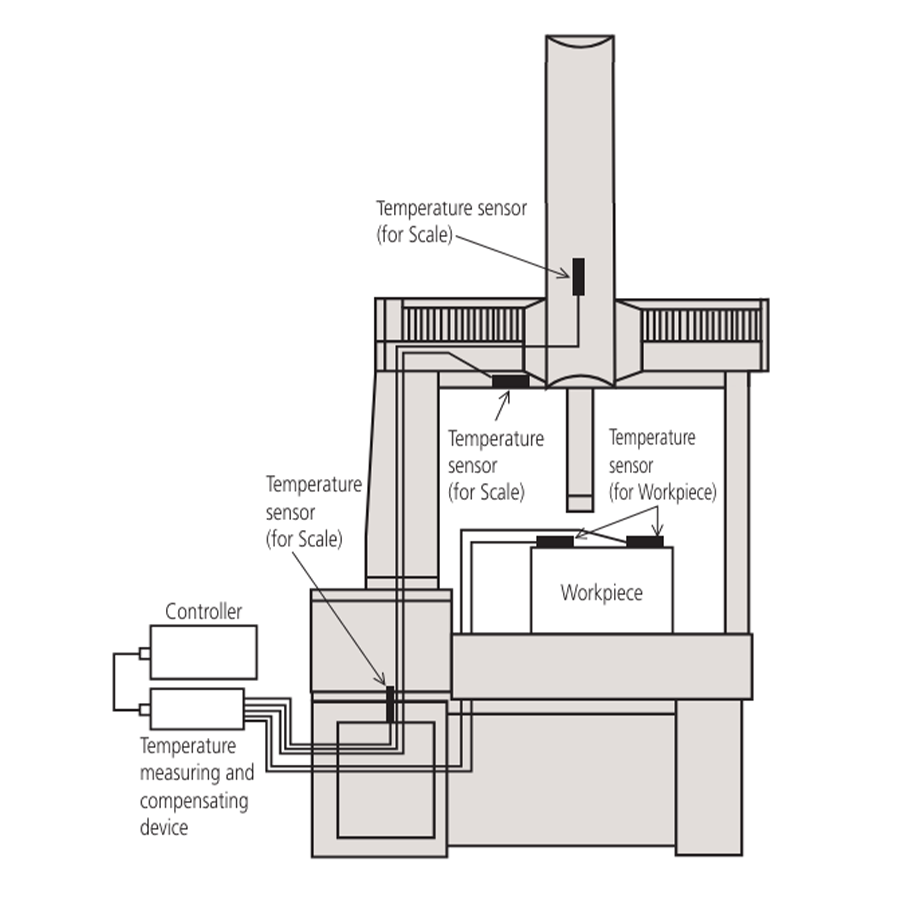

Real-time temperature compensation:

In the past, the accuracy of CMMs could not be guaranteed unless they were installed in constant temperature rooms. The temperature compensation feature guarantees accuracy under temperature conditions of 16-26 °C. This feature measures the temperature of the workpiece and that of the measuring machine, calculates what the measurement value would be at 20 °C, and outputs this value as the measurement result.

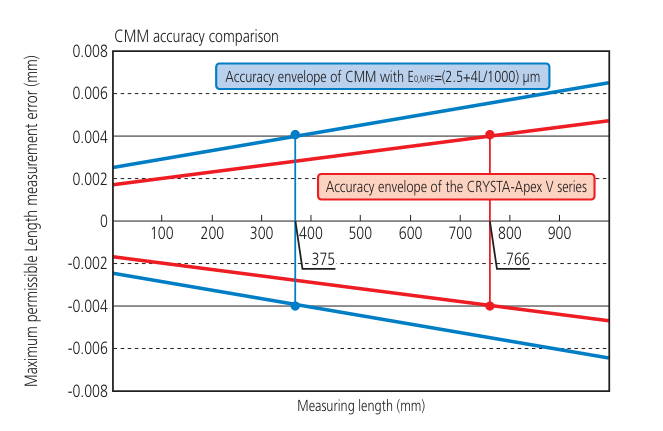

High accuracy

The CRYSTA-Apex V Series guarantees a maximum permissible length measurement error or E0, MPE, of 1.7+3L/1000 µm. Let’s consider a CMM offering E0, MPE of approximately 2.5+4L/1000 µm, which would generally be considered high-accuracy. If, for example, the required tolerance on a dimension is±0.02 mm, the uncertainty of this machine would exceed one-fifth of this value* (±0.004 mm, as shown on diagram at right) for any measured length over 375 mm. In contrast, with the V Series, the measurement uncertainty remains within one-fifth of the required tolerance for measuring lengths up to 766 mm. Although the difference in the first term accuracy specification between the two machines may seem small (a mere 0.8µm), the V Series actually offers guaranteed accuracy for more than double the measuring range.

Repetitive accuracy

To eliminate causes of dynamic error and to deliver high repeatability, data from measurements using scanning probes are processed for stabilization. The probe is kept motionless for a few seconds when its tip first contacts the workpiece, thereby ensuring that causes of dynamic errors are eliminated as much as possible and making it possible to deliver highly accurate measurement results.

HIGH SPEED

Dramatically reduces measurement time with high-speed measurements for any shape.

The V Series lets users freely set measurement paths along three-dimensional forms, enabling intricate workpieces to be measured along their curved surfaces and contours.

It also allows for high-speed measurement unaffected by processing accuracy or misregistration through real-time correction of path errors caused by differences between the workpiece and design values. The V Series, with its high drive speed and acceleration dramatically reduces the total measuring time.

Speed and acceleration to reduce measurement time

The CRYSTA-Apex V Series offers a maximum drive speed of519 mm/s and a maximum acceleration of 2,309 mm/s2.The V Series with its high drive speed and acceleration combined with measuring speeds up to 120 mm/s, significantly reduces total measuring time.

The greater the number of measurement requirements, the more time savings realized. This in turn results in a cost savings, increased inspection throughput, and more workpieces inspected thereby increasing the quality assurance.

High-speed optimal path scanning

The V Series is equipped with a measurement feature that allows users to specify scanning measurement paths(design values). This feature allows for high-speed, high-accuracy scanning by correcting dynamic errors that would otherwise be produced by acceleration and deceleration stresses.

Measurement paths can be freely specified for three-dimensional forms as well, which enables intricate workpieces to be measured by tracking precisely along their curved surfaces and contours.

Active scanning feature

Enables high-speed measurement unaffected by processing accuracy or probe path control errors while maintaining the advantages of 3D optimal path scanning measurement, by limiting discrepancies between design values and the actual workpiece.

The intricacy of some workpieces (e.g. turbine blades, fan blades, and impellers) causes their processing accuracy to fluctuate or makes them more susceptible to probe path control errors. Probe path control errors during measurement are often aborted.

The V Series enables smooth measurement of such workpieces.

DIVERSITY

Enables highly accurate and highlyefficient measurement ofworkpieces of practically any shape

The V Series lets users freely set measurement paths along three-dimensional forms, enabling intricate workpieces to be measured along their curved surface sand contours.

It also allows for high-speed measurement unaffected by processing accuracy or misregistration through real-time correction of path errors caused by differences between the workpiece and design values. The V Series, with its high drive speed and acceleration dramatically reduces the total measuring time.

Probes for Coordinate Measuring Machines

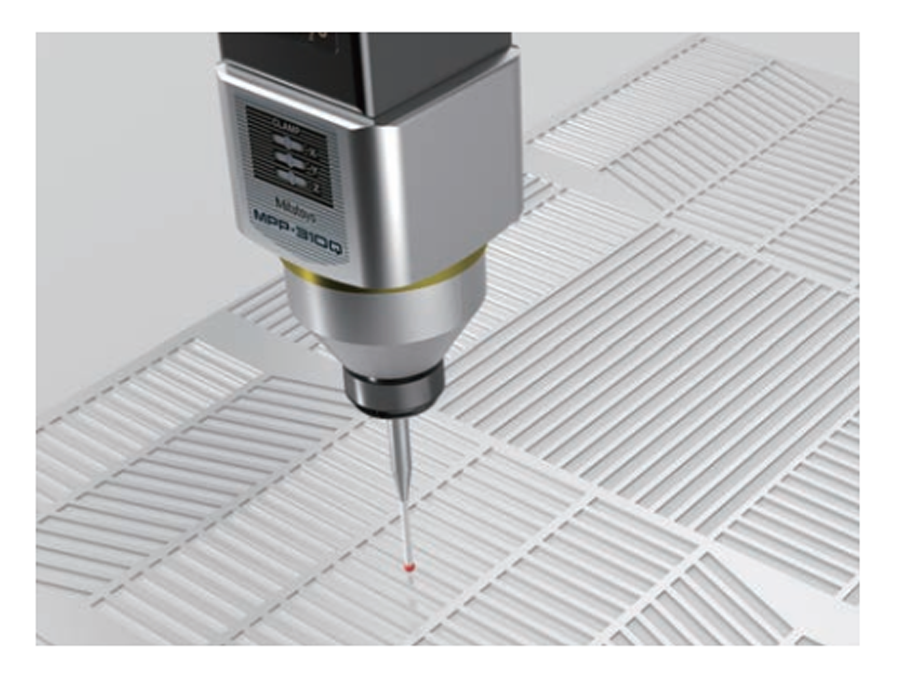

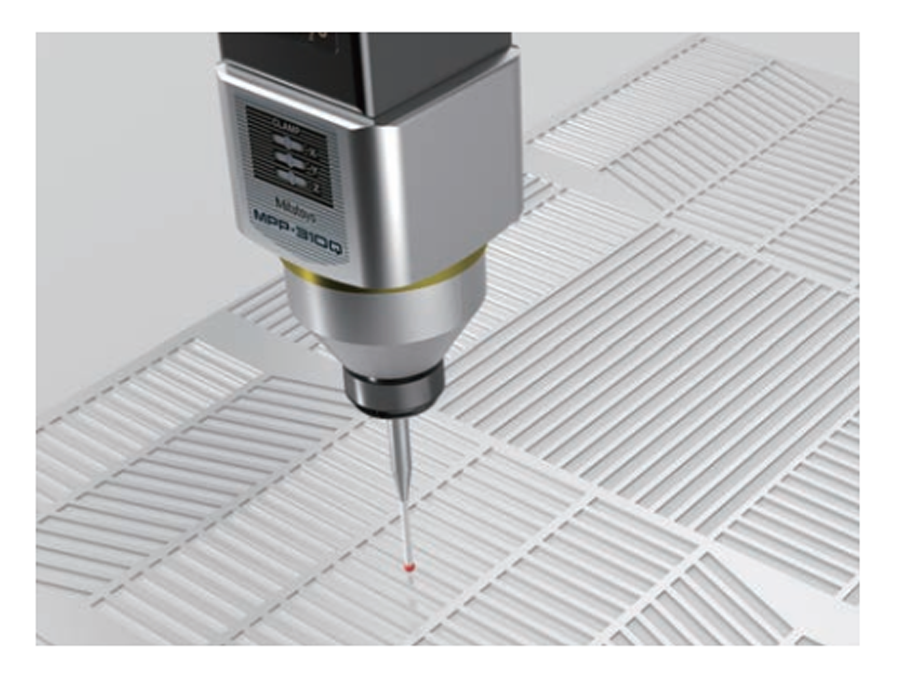

Compact high-accuracy scanning probe SP25M

The SP25M is a compact, high-accuracy scanning probe with a 25-mm outside diameter.

It is a multi-function CNC CMM probe that can collect data from not only scanning measurements (where SP25 moves while in contact with the workpiece collecting up to 10,000 points/sec) but from high-accuracy point measurements as well.

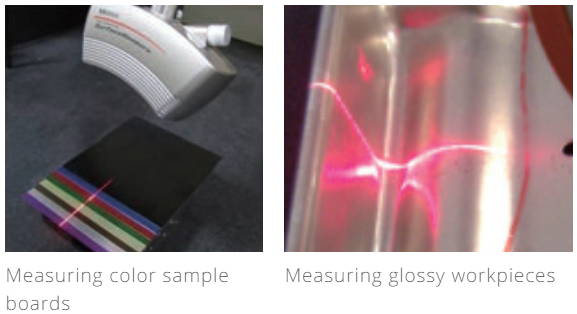

Non-contact laser probe Surface Measure

Surface Measure is a laser probe that collects coordinate values of the surface of the workpiece by moving and irradiating laser light over the workpiece.

It can quickly obtain massive amounts of 3D surface data.

Automatic probe changer ACR3

Necessary when using probes that do not support automatic stylus exchange for fully automated measurements that require changes in stylus diameter and/or length. Also necessary for fully automated measurements that require switching between contact and non-contact probes. Now with a simpler structure and increased durability, as a result of a new mechanism that uses the drive of the CNC CMM for automatic exchange.

Enables efficient, high-accuracy measurements of a wide variety of workpieces

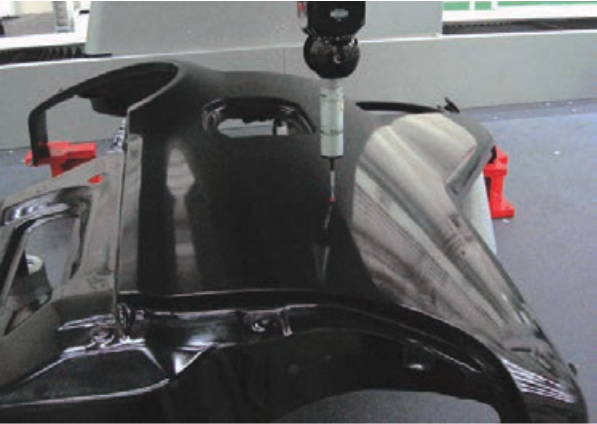

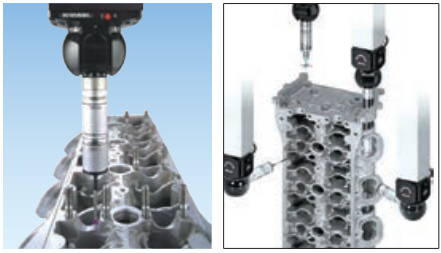

We have many applications for the CRYSTA-Apex VSeries, such as scanning probes and non-contactprobes, that enable measurement of a wide range ofworkpieces.

Separator molds

Surface and cross-section measurements of precision molds for separator scan be conducted using a low measuring force, high-accuracy scanning probe. Three-dimensional error analysis and cross-sectional form analysis may be performed based on the obtained measurement points.

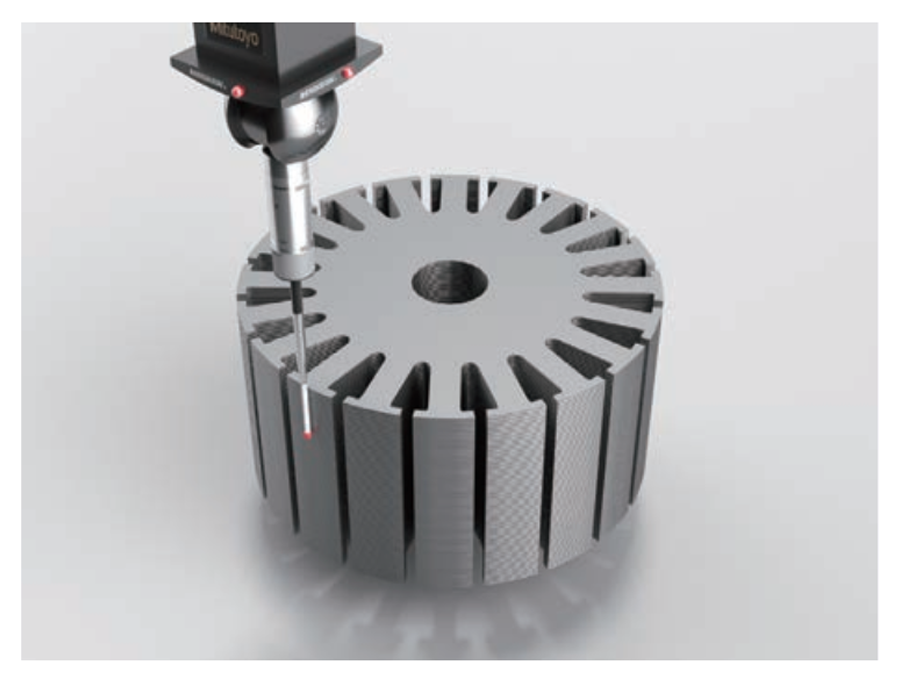

Impeller

Impellers can be measured using a highly robust non-contact laser probe that reduces multiple reflections. Just as accurate as contact probes, this probe offers high geometric reproducibility.

Motor cores

The V Series can measure the straightness, cross-sectional form, etc. of laminated motor cores. It can also conduct measurements of

three-dimensional structures, including measurements of side faces and dimensions at arbitrary heights.

Blade

The cross-section of an aircraft engine turbine blade can be measured using a compact, high-accuracy scanning probe. Even workpieces susceptible to large

errors, such as castings, can be measured quickly and reliably.

Artificial joint

Freeform surface measurement of prosthetic joints can be conducted using a compact, high-accuracy scanning probe. Three dimensional error analysis may be performed based on the obtained measurement points.

Transmission cases

Non-contact laser probes require dramatically less measurement time compared to contact (scanning) probes. Scanning at once from three directions enables simultaneous measurement of the top and side faces, which means less repositioning and efficient measurement of even the most intricate workpieces.

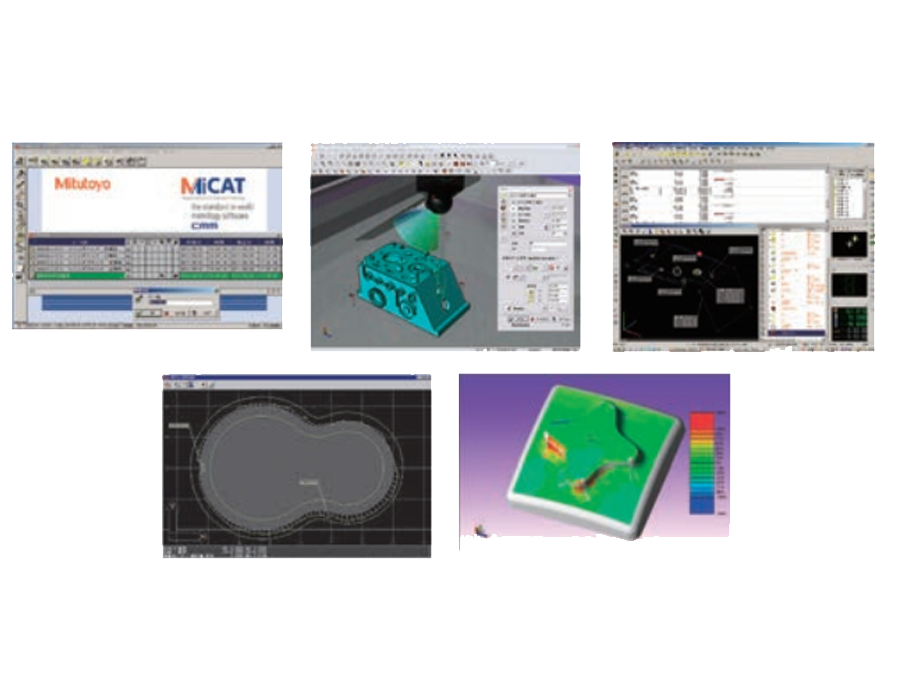

SOFTWARE

Application software that offers both functionality and operability.

We offer an extensive lineup of application software for generating measurement programs automatically and performing evaluations using CAD. From simple to complex measurements, they can resolve any measurement issues that our customers may encounter.

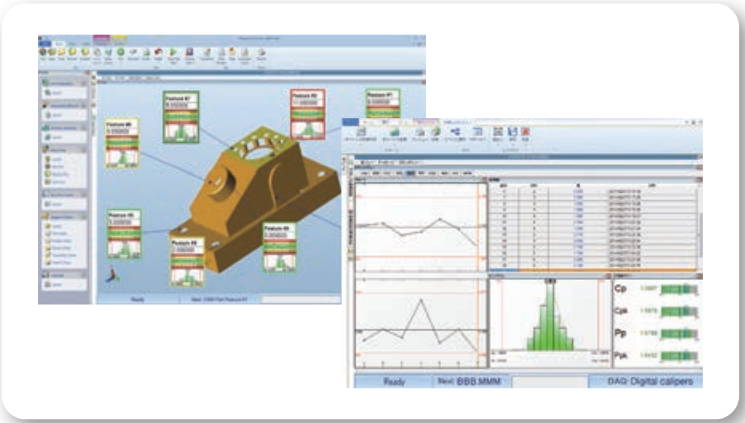

MCOSMOS

Data Processing System for CMMs

MCOSMOS is a family of Windows-based processing programs for CMMs. It includes an extensive lineup of optional software applications that support a wide range of probes, enabling fully automated measurement of all kinds of workpiece.

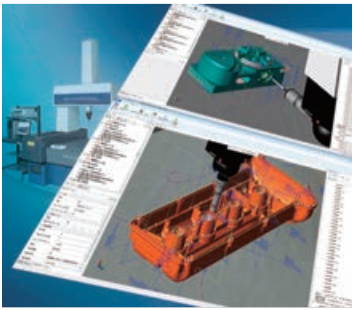

MiCAT Planner

Automatic Measurement Program Generation Software

Software automatically generates measurement programs by reading tolerance information added to 3D CAD models to determine which part of the workpiece should be measured. Compared to conventional methods (teaching), this method can create measurement programs more efficiently.

MSURF

Automatic Measurement Program Generation Software

MSURF is a package program comprised of MSURF-S for scanning and MSURF-I for inspection. Its functions include comparing and checking measurement point data (obtained using MSURF-S) against master model data, and measuring dimensions (MSURF-I).

SMART FACTORY

From status management to preventive maintenance. Kickstart your smart factory through visualization.

Mitutoyo has developed the Smart Measuring System (SMS),

a new system that use a network to centrally manage

manufacturing process information and data visualization.

Data visualization includes MeasurLink ® for predicting defects

by collecting and analyzing measuring machine data in real

time; Status Monitor that tracks operational status of the

measuring machine for optimal machine scheduling and

performance; Condition Monitor, which indicates the condition

of the machine itself, to help maintain measurement accuracy,

increase productivity, and improve maintenance management.

STATUS MONITOR

Can remotely monitor measuring machines.

• Collects and visualizes operational

status data

• Supports MT Connect communication

Condition Monitor

Conduct preventive maintenance through monitoring

MeasurLink ®

Reduces defective products by visualizing quality

USABILITY

Effectively reduces operation and measurement time through enhanced convenience and usability.

Equipped with the Quick Launcher, which improves operability, and a joystick box includes precision control and functions to facilitate measuring intricate workpieces with speed and ease.

Such enhancements in usability work to streamline the workflow by reducing measurement time.

Part program execution

Equipped Parts program execution is equipped standard with the Quick Launcher, which enables simple and intuitive operation for easy execution.

The touch panel monitor improves operability, making operations effortless for anyone.

Part programs can also be executed via barcodes and QR codes.

Joystick box

The joystick box allows users to easily operate their CRYSTA-Apex V Series CMM. It comes with control buttons marked with user-friendly icons and an override knob for changing speed.

MiCAT Planner

Software automatically generates measurement programs by reading tolerance information added to 3D CAD models to determine which part of the workpiece should be measured. Compared to conventional methods (teaching), this method can create measurement programs more efficiently.

OPTIONS

Supports fully automated measurements and efficient setting to broaden options for applied measurements

Supports fully automated measurements that capitalize on the advantages of CNC CMMs.

Also supports efficient setting to broaden options for applied measurements by, for example, providing clamping tools that enable users to fix various workpieces more easier.

Automation example

The V Series’ ability to deliver high-accuracy measurements across a wide temperature range eliminates the need for a dedicated measuring room.

This allows for the automation of in-line and line-side measurements within the manufacturing process (i.e. on the manufacturing line), which significantly reduces measurement time and streamlines the workflow.

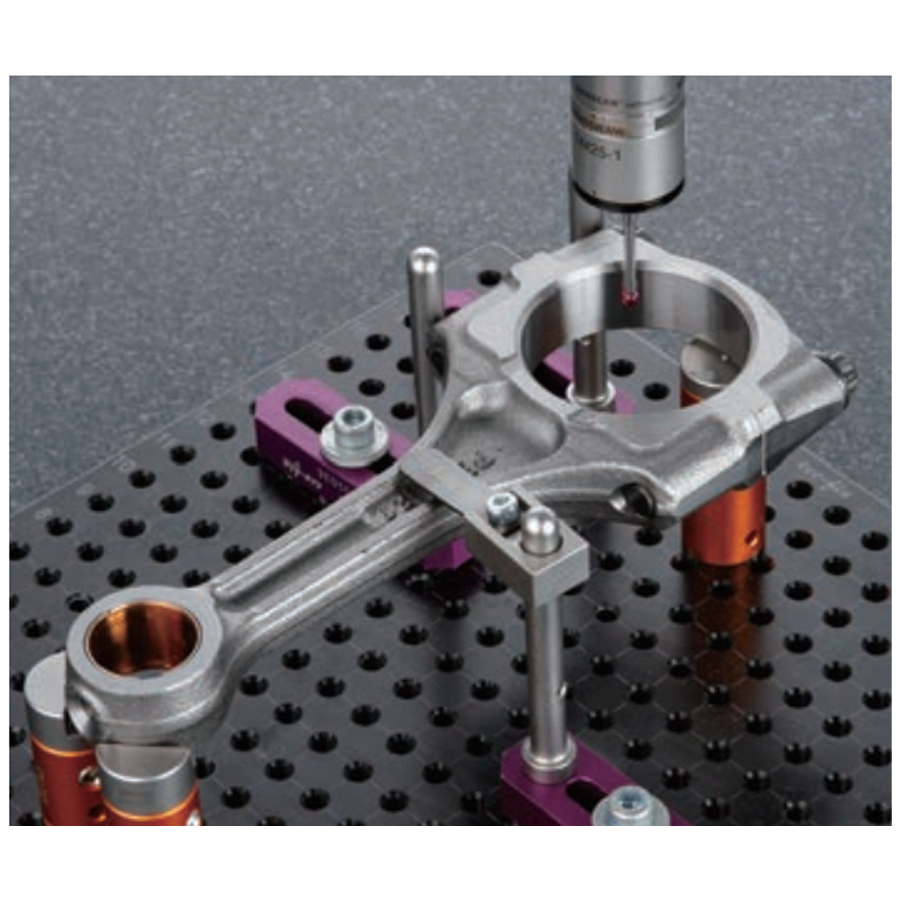

Clamping system Eco-Fix Kit

Mitutoyo clamping tools comprised of a clamping system where

elements can easily and quickly be assembled to affix various workpieces.

Rotary table

Optional measuring device for CNCCMMs developed for efficient andhigh-accuracy measurement ofmainly rotary workpieces (gears,impellers, screw rotors, cylindricalcams, etc.). Can be used togetherwith a scanning probe forsynchronized scanningmeasurement, enabling a wide rangeof contour measurementsbroadening the range of applied measurements.

Our Mission & Vision

Whatever your challenges are, Mitutoyo & our team at GreatGages.com supports you from start to finish!

Mitutoyo is not only a manufacturer of top quality

measuring products but one that also offers qualified

support for the lifetime of the equipment, backed

by comprehensive services that ensure your staff can

make the very best use of the investment.

Apart from the basics of calibration and repair,

Mitutoyo offers product and metrology training,

as well as IT support for the sophisticated software

used in modern measuring technology.

Mitutoyo can also design, build, test and deliver measuring solutions and even, if deemed cost-effective, take your critical measurement challenges in-house on a sub-contract basis.

Need a Quote?

Give us a call or mail us by anytime, we strive to answer all inquiries within 24 hours on business days. We will be happy to answer any and all of your questions.

Toll Free: 866-460-1942

Email: sales@greatgages.com