QC-CALC GageStation

GageStation is a combination license of both QC-CALC Real-Time and QC-GAGE. This combination license creates 1 data collection station for use with hand tools and manual data entry.

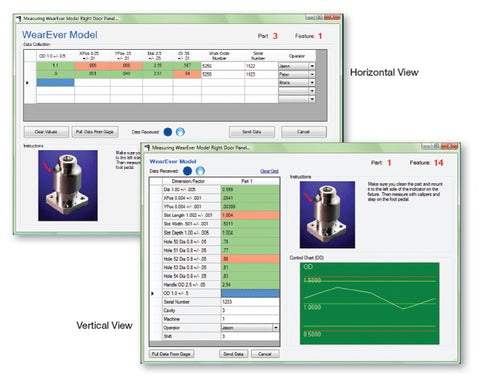

QC-Gage is a full-featured data collection application for use with hand-held gages. The software allows inspectors to enter measurement data by keyboard or through a direct connection to one or more gages. It displays this data both graphically and in table form, and automatically interfaces with QC-CALC Real-Time. By using GageStation, you can identify and isolate out-of-conformance parts.

Key Benefits

- Easy Single-button launch

- Interface with all electronic gages, RS-232 or USB

- Your choice of Gage Interface Boxes

- Keyboard entry for mechanical gages

- Spec plans provide consistent input

- Easy to write Spec Plans for each part type measured

- Provide text instructions for operators

- Include Photos of inspection technique for operator reference

- Graphical feedback as inspection occurs

How it Works...

QC-Gage simulates the inspection technique of an automated inspection device such as a CMM. You program QC-Gage through a simple wizard by answering questions that describe the sequence your inspectors must follow. These "Spec Plans" are saved and run by your inspectors, leading them in a consistent sequence of inspection. When all data and trace information (serial number, lots, names, etc) is entered, it is sent to QC-CALC where the Real-Time statistics are performed.

Shop now for QC-CALC GageStation Software

The Spec Plan

Each Spec Plan you create is a complete definition of the part to be inspected and the process used to inspect the part. You can create as many Spec Plans as needed to support the variety of parts you inspect. When writing a new Spec Plan, you define each feature in detail. When the Spec Plan is run, QC-Gage displays the instructions given for each feature along with an optional picture, The data is plotted in a graph, which is scaled based on the given Nominals and Tolerances.

QC-Gage provides the tools and flexibility you need to easily manage data for virtually any type of part. Using the setup wizard, you quickly construct a specification plan (Spec Plan) that includes a part diagram, customized instructions, and your own trace field details.

|

for QC-CALC GageStation Software |

Download 30 Day Free Trial... |

Related Links

QC-CALC Real-Time

This module is used to collect and display measurement results from all CMMs, Video CMMs, and hand gages without operator intervention. You can create reports and export data to spreadsheets, databases, and other SPC programs. This means you can transfer data from all of your measurement devices to any SPC package using one program!

This is the first program to provide one interface for all machines and one interface for all outputs. Prolink's goal is to make your data collection seamless no matter what equipment you’ve purchased or software you use.

Click Here for more QC-CALC Real-Time information

Shop now for QC-CALC Real-Time

QC-CALC Office Buddy

SPC Office Buddy integrates directly with Minitab, JMP and MS Excel to run reports using the data that was collected on your CMM, Vision System, and at your Gage Stations. Office Buddy will allow you to run Minitab reports with the click of a button.

SPC Office Buddy also has the ability to create custom reports in MS Excel. Without using any Excel macros, Excel Jobs addresses the periodic weekly or monthly reports, such as PPAPs, that are very labor-intensive, time-consuming activities.

Click Here for more QC-CALC Office Buddy information

Shop now for QC-CALC Office Buddy

QC-CALC SPC Reporting Software

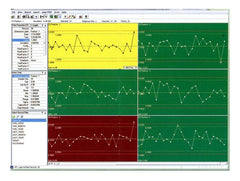

This software is designed to analyze the data collected by QC-CALC Real-Time and QC-Gage. Use QC-CALC SPC's charts and reports to constantly monitor your process and keep it in control.

QC-CALC SPC offers a wide variety of charts and functions to aid your analysis and give you the power to make on-the-spot decisions. In seconds, QC-CALC SPC gives you a precise picture of how your production line is performing with easy-to-use menus.

Click Here for more QC-CALC SPC Reports information

Shop now for QC-CALC SPC

QC-CALC EDL - Enterprise Data Loader

If you would like to have your data saved in an SQL database for advanced reporting purposes, you will need QC-CALC's Enterprise Data Loader, or EDL.

The Enterprise Data Loader (EDL) typically resides on a central server at each plant and is responsible for synchronizing data from QC-CALC with data in a SQL database. EDL is actually two applications; the EDL Client and EDL Load Service. The EDL Client is a normal Windows application that provides a fast and easy way of setting up the loading events for the EDL Load Service. The EDL Load Service moves your CMM and gage inspection results directly into the SQL database at the scheduled frequency.

Shop now for QC-CALC Enterprise Data Loader

QC-CALC ERS - Enterprise Report Scheduler

The reports generated by ERS are designed to provide a rolled-up overview of the quality conditions within your plant or across plants. Rather than simply reporting on one part, you run reports that compare the capability of all features across all parts, cells, or even plants.

To run ERS, you would need Enterprise Data Loader, or EDL, to gather the data that has been collected from your CMMs, Vision Systems, and Gage Stations, and transfer that data to a central SQL database. ERS then generates automated reports that provide an overall view of your factory's performance.

Click Here for more QC-CALC ERS information

Shop now for QC-CALC ERS

|

Click Here |

Click Here |

Click Here |

Need a quote before you can buy? |

|

We understand that often times the customer will need an "official" quote for software like this before they can make a purchase. The link to the right will take you to Prolink's website where you can see all of the software modules available, as well as costs. If you add items to the cart on Prolink's site, you will be given an option to generate a quote that you can save / print out. |

Login to Prolink's website to generate a quote. |