Hardness testing plays a pivotal role in the field of mechanical engineering, offering valuable insights into a material's resistance to deformation. In this blog, we will delve into the intricacies of hardness tests, exploring their significance and the methodologies employed to assess hardness levels. From macroscopic to microscopic scales, hardness tests provide crucial data that aids in understanding material properties.

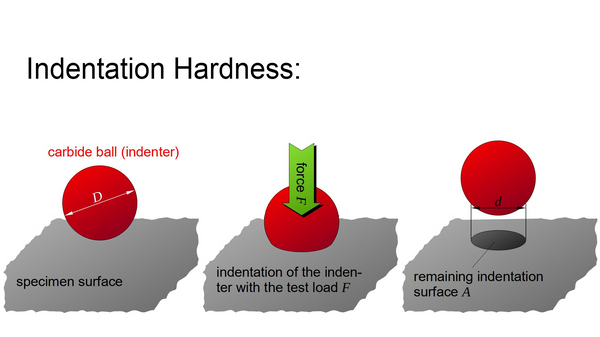

Understanding Indentation Hardness:

One of the fundamental concepts in hardness testing is indentation hardness, wherein the material undergoes indentation until an impression is formed. Particularly in testing metals, there exists a rough linear correlation between indentation hardness and tensile strength. However, it's important to note that this correlation is imperfect and often limited to specific ranges of strength and hardness for each indentation geometry.

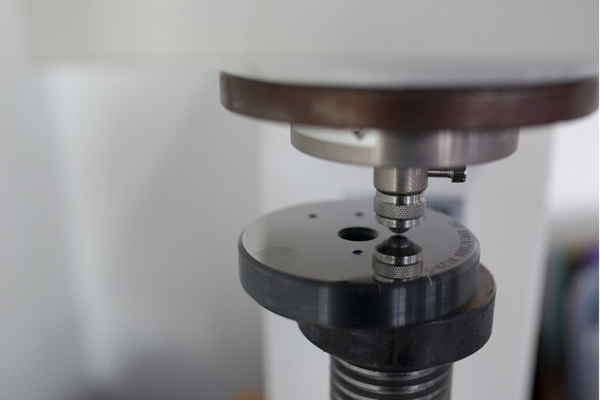

Nondestructive Testing with Portable Equipment:

One remarkable application of hardness testing is in nondestructive testing of bulk metal deliveries. This is made possible through lightweight and portable equipment, such as hand-held Rockwell hardness testers. These devices offer a convenient way to assess the hardness of metals without causing damage, making them economically valuable for various industries.

Rockwell Hardness Testing Methodology:

The Rockwell hardness test is a widely used method for assessing material hardness. It involves the application of both minor and major loads. The minor load establishes the zero position, while the major load is applied and then removed while still maintaining the minor load. The depth of penetration from the zero datum is measured from a dial, where a higher number indicates a greater hardness for a harder material.

Inverse Proportionality: Penetration Depth vs. Hardness:

One intriguing aspect of Rockwell hardness testing is the inverse proportionality between penetration depth and hardness. Essentially, a harder material will result in a higher number on the Rockwell hardness scale. This characteristic simplifies the process of obtaining hardness values directly, eliminating the need for tedious calculations associated with other hardness measurement techniques.

In conclusion, hardness testing serves as a cornerstone in the field of mechanical engineering, providing critical information about a material's ability to withstand deformation. The Rockwell hardness test, with its practical and efficient methodology, stands out as a valuable tool for assessing hardness levels in a wide range of materials. As industries continue to rely on hardness testing for quality control and material selection, understanding the science behind these tests becomes increasingly essential.

For more information, and to shop our Hardness Tester Collection: Click Here!